SUMIT WOVEN STRUCTURED PACKING is excellent for applications that require a large number of theoretical stages, lower pressure drop and small overall packed bed heights. (Exhibit all the features & advantages of the SUMIT Sheet-Metal STRUCTURED PACKING)

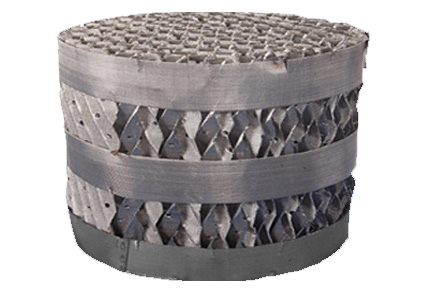

The SUMIT WOVEN STRUCTURED PACKING is manufactured from specially woven wire gauze that is pressed into smooth plates, uniformly perforated, corrugated and stacked with corrugations in alternate 90o degree directions arranged vertically in close contact to form modules. The special perforated mesh provides high intimate gas \ liquid contact and a good lateral distribution of liquid in all direction and uniform wetting of the packing.

This packing is well suited for application that require high separation efficiency and minimum hold up. Due to Ultra-high-efficiency of column packings they are extremely advantageous in pilot plant trial and laboratory distillation systems also.

The high surface area of uniformly perforated wire gauge provide maximum exposure between the liquid and vapour phases, thus providing a very high mass transfer efficiency. Therefore, a lower number of theoretical stages. It provides low pressure drop at higher load capacity. Because of its low pressure drop and minimum holdup characteristics, SUMIT WIRE gauze packing is an ideal mass transfer medium for temperature-sensitive systems.

Sumit woven wire gauze packing is available in a variety of standard types. SUM WM X & SUM WM Y. Gauze packing is designed for applications requiring a high number of theoretical stages with very low pressure drop. Gauze packing is designed for use in smaller diameter towers for separations which require a maximum number of theoretical stages.

ApplicationsSUMIT WIRE GAUGE can handle vaccum distillation problems. Its low pressure drop per theoretical stage and minimum hold up characteristics this packing makes it ideally suited for vaccum distillation. Its superior performance over a wide operating range makes it an excellent choice for use in multipurpose rectification also. as well as suitable for temperature sensitive compounds, low-liquid loading systems, isomer separation, Hence suitable in Isomer separation pharmaceuticals intermediates fine chemicals, flavors and fragrances, Essential oils and Perfumery. Electronic chemical Specialty chemicals, fatty acids & alcohols dye stuff industries Essential oils and Perfumery.

A typical case of SUM WM X & SUM WM Y Packing in comparison with Pall ring is:| SUM WM X | SUM WM Y | Pall Ring | |

| Contact Surface Area (m/m) | 500 | 700 | 100 |

| F Factor (Kg ½ / sec. M ½ ) | 2.0 - 2.5 | 1.5 - 2.5 | 2.0 - 4.0 |

| NTSM (Number of theoretical stages Per Meter) | 5 | 8 | 1.2 |

| PDTS (Pressure Drop Pe Theoretical stages, mm Hg) | 0.27 | 0.4 | 1.7 |

Sumit also design and manufacture high efficiency column internals (Distributors, Collections, Support Grids etc) good initial distribution together with systematic redistribution is critical to optimum tower performance.Performance curves for Ever pack SMY 250 as well as the other packing versions are Available on request Sumit sheet metal structured tower packing provides high capacity, wettability and low pressure drop in a number of distillation, absorption and liquid / liquid extraction applications including: